Weight monitoring on the BCW cocktail machine

Single-point load cells and intelligent junction boxes: an advantageous, space-saving solution.

Bayerische Cocktail Werke is a company based in Dorfen, Bavaria, that has been making BCW cocktail machines for festivals, clubs, bars, amusement parks and stadiums for over 15 years.

By combining a cloud-based digital system and a “bag-in-box” ingredient storage system, the machine can store over 50 ingredients to produce an unlimited number of cocktails and deliver up to 20 per minute.

Requirement

Allowing the Bayer cocktail machine to monitor the weight of the individual bags of ingredients contained in the drawers so that the bags can be replaced before the machine is left without any.

Thanks to precise weight monitoring, the operator is in fact alerted in advance of the lack of an ingredient, so cocktails are always perfectly dosed to the milliliter.

The position of the drawers, inserted in a frame, also requires compact weighing instruments, while the machine’s production margin requires them to be high performing but cost-effective, in order to contain costs for the installing customer.

Our solution

To meet the customer's needs, we have used:

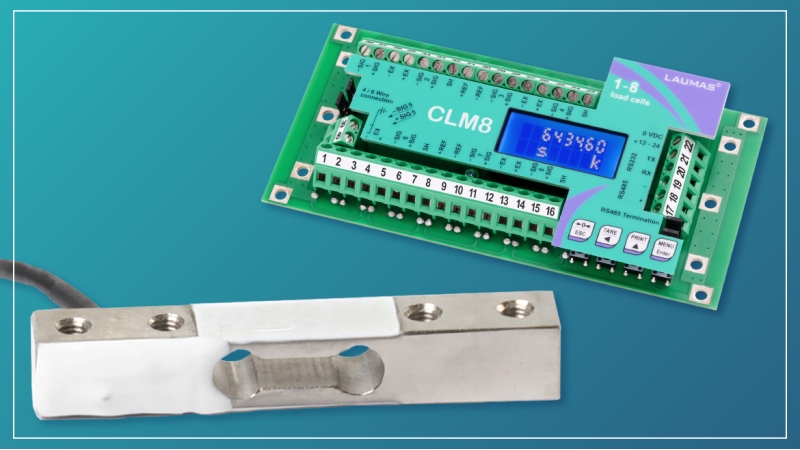

- 80 AF single-point load cells of 15 kg

- 10 CLM8 intelligent junction boxes, in the “board-only” version.

How does it work?

The operator selects the required type of cocktail with the touchpad and, depending on the recipe, the machine takes the liquids from the containers and dispenses them into the cup.

The AF load cells are placed inside the frame under each drawer, and eight load cells are connected to each CLM8 junction box.

Using the CLM8's independent inputs, the reading divisions of the eight load cell channels are transmitted unfiltered to the PLC.

Once the divisions are converted into a weight signal, the eight load cells can be managed using a single CLM8.

A weight threshold is set on the PLC, below which the machine signals the operator that a certain ingredient is running low.

The added value

- The AF load cells are small and thin, so they fit inside the structure perfectly without creating any thickness.

- The “board-only” version of CLM8 is our smallest and most cost-effective multichannel solution, while maintaining all the functions of the box version. The board is very small (151 x 72 x 30 mm) and permits saving space and money.

- The small size of the instruments permits saving space for more drawers and therefore being able to use more ingredients.

- CLM8 transforms the analog signal of the load cell into a digital signal and transmits it to the PLC, simplifying the communication of the weighing data.

RELATED PRODUCTS

AF

Single point load cells

CLM8 - CLM16

Weight transmitters