CBL load cell & V10000 mounting kit

In 1995, a meeting became the perfect fit between versatility and innovation.

A historic relationship

She is CBL, the compression-low profile load cell.

He, her inseparable mounting kit V10000.

She was born in 1987 and was one of the first load cells LAUMAS produced.

He joined her in ’95, with a compact design conceived to fit perfectly with her and exalt her practicality.

CBL and V10000 are products completely Made in Italy, both in design and in construction.

A great classic of our production.

Together, CBL and V10000 are LAUMAS' best-selling products: 39 501 load cells and 29 796 mounting kits within the last 5 years alone.

The versatility of CBL...

- The capacity range is from 250 to 100,000 kg, which is why it is used in the most varied systems;

- it is made of 17-4 PH stainless steel;

- it has an IP68 protection rating.

Completely dust-proof and waterproof, it can be used in aggressive environments and particularly demanding industries (food industry, chemical and pharmaceutical industry…); - on request, it is IECex and ATEX certified, for installation in potentially explosive areas;

- it is OIML R 60 approved for legal for trade use;

- there is also a “redundant” version with two output cables, for double safety systems in which the load cell also acts as a load limiter, such as those for lifting.

...and the innovation of V10000

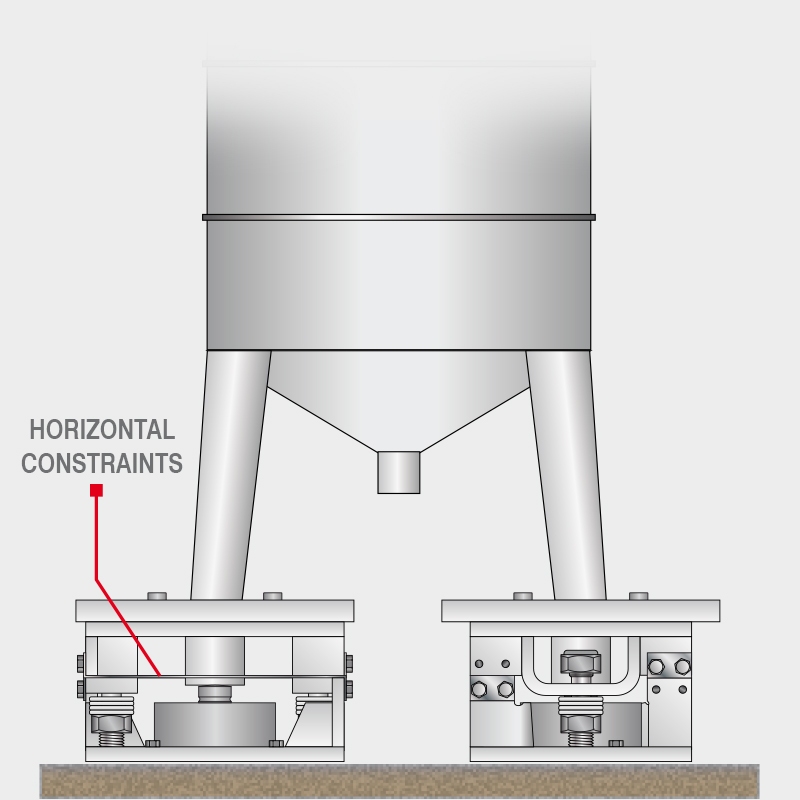

Made entirely of AISI 304 stainless steel, the V10000 mounting kit has introduced a major new feature: the anti-tilt constraints and lateral forces constraints, which allow it to ensure stability for the structure on which it is installed.

Applications such as silos, tanks and hoppers can be subject to accidental impact, wind forces, earthquakes... that can damage the weighing system.

V10000 helps prevent this because it contains

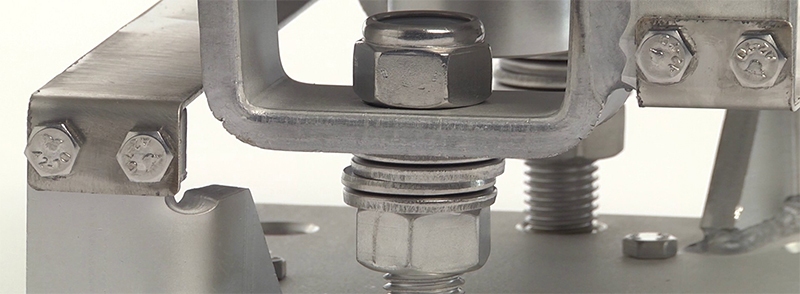

- steel plates acting as constraints against lateral forces

- two threaded rods with self-locking nuts as an anti-tilt system

that protect the load cell from potentially damaging stresses and allow it to work properly.

A perfect combination

The main strength of CBL and V10000 lies precisely in their combination, which assures simple and safe installation: the kit is secured to the structure to be weighed without the load cell inside it.

This ensures that welding and assembly can be carried out entirely safely because the load cell is inserted later and there is never any risk of damaging it.

At the same time, it also becomes much easier to replace the load cell in the event of it getting damaged: simply remove it from the accessory without dismantling it, and insert a new equivalent load cell.