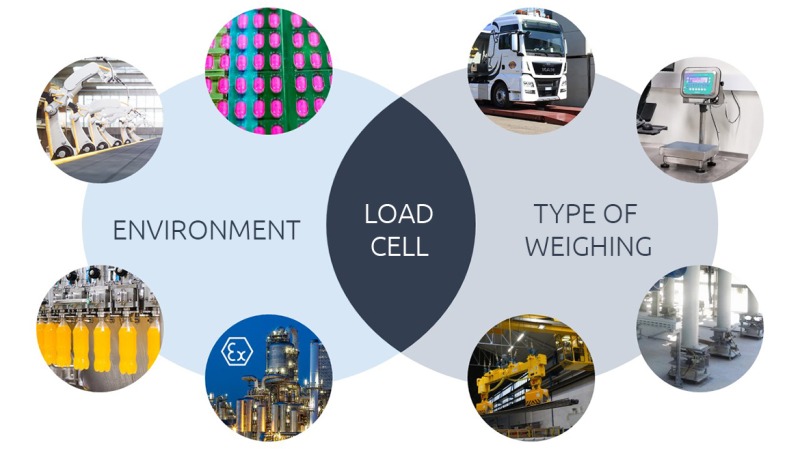

How to choose a load cell? The factors to assess

Analyzing environmental conditions and type of application to select the most suitable load cell.

How to choose one load cell compared to another?

To meet the manifold needs of a weighing system, what specifications do we have to take into consideration, and in relation to what variables?

To define the most suitable load cell it is necessary to assess several factors, both external ones and ones inherent to the very application for which the weighing system is intended.

In particular, it is necessary to pay attention:

- to the environmental conditions in which the system will be working (WHERE will we be weighing?)

- to the type of application in itself: the characteristics of the structure to be weighed and its operation, as well as the subject and purpose of the weighing itself (HOW, WHAT and WHY will we be weighing?)

Analyzing these discriminating factors allows us to better orient ourselves among the different types of available load cells and among the many specifications the load cell must have.

We will thus know how to select the most appropriate standard load cell or to provide the necessary details for a custom solution.

→ Read also The main types of load cells

→ Read also How to choose a load cell? Technical features guide

Contents:

1. WHERE DO WE WEIGH? Assessing the environmental conditions of the weighing system

2. HOW DO WE WEIGH? Assessing the application and type of plant in which the weighing system is installed.

3. WHAT DO WE WEIGH? Assessing the object to be weighed.

4. WHY DO WE WEIGH? Assessing the reason for weighing.

1. WHERE DO WE WEIGH?

Assessing the environmental conditions of the weighing system.

The environment affects the performance of load cells, so it is fundamental to analyze the conditions in which they are going to work in order to select the most appropriate characteristics.

We will have to carefully consider the degree of severity of the environment that is going to accommodate the weighing system, both as regards the natural and special weather conditions and as regards the conditions more closely related to the type of plant and industry of the application.

Specifically, we will have to ask some helpful questions:

Will the load cell be installed indoors or outdoors where it is not protected from the weather?

Is the application environment dusty? Damp?

Will the load cell be subjected to immersion? If so, to what depth? Will they be temporary or continual immersions?

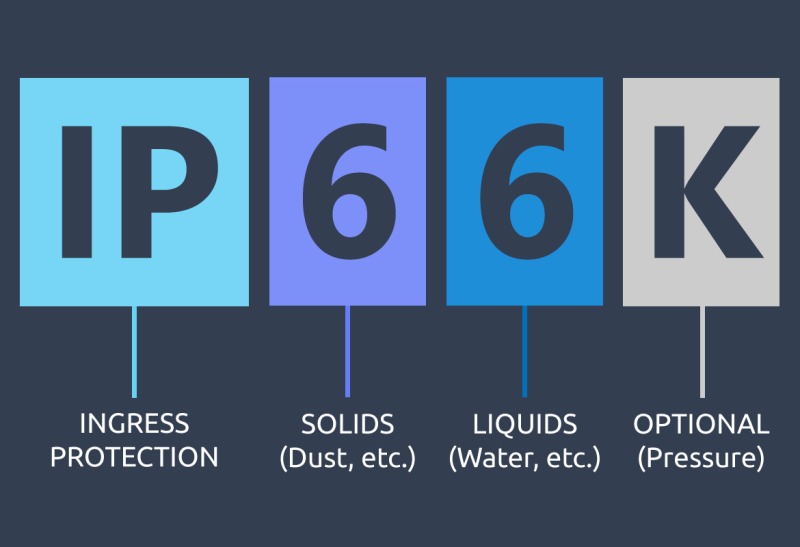

❖ It will first of all be necessary to consider the required IP protection rating, that is the level of resistance against the ingress of dust and/or water into the sensor.

The protection rating is indicated by the (Ingress Protection) IP code followed by 2 digits.

The first one indicates the protection rating of the enclosures of electrical equipment against the ingress of solid objects (for example, dust) and can range from 0 to 6.

The second digit instead indicates the level of protection against the ingress of liquids and can range from 0 to 9, with specific digits for resistance against jets of water under greater or lesser pressure or against immersions of different duration and depth.

LAUMAS load cells, for example, provide IP65 and IP69K protection ratings against jets of water and IP67 and IP68 against immersions.

The IP code, which describes the protection rating of the enclosures of electrical equipment.

❖ All these conditions also affect the choice of the construction material of the load cell.

For example, if the application is in a dusty environment, but indoors, aluminium or a non-stainless steel can be sufficient.

Whereas, if it is outdoors or exposed to liquids or aggressive agents such as chemicals, it will be necessary to consider stainless steel 420 as a basic requirement, to then reach stainless steel 17- 4 PH that is the one most resistant to corrosion.

What are the minimum and maximum temperatures at which the load cell will be working?

All materials undergo changes according to the temperature, expanding in response to heat and contracting in response to cold.

This then also applies to load cells and their strain gauges.

Environments with out-of-standard temperatures (very hot or very cold) can condition the deformation of metal and entail alterations in the electrical resistance of the conductor.

The same happens in the case of considerable thermal excursions.

❖ For load cells to correctly measure the weight regardless of the ambient temperature, during production each load cell undergoes a thermal compensation treatment.

This allows them to work within the temperature range specified on the data sheet observing the reported temperature errors (effect of the temperature on zero and effect of the temperature on full scale).

The standard thermal compensation of LAUMAS load cells is normally -10+40 °C, but in the case of exceptional thermal conditions we build custom load cells with thermal compensation and special cables for high/low temperatures.

Custom load cell made by LAUMAS, with a special cable for high temperatures.

❖ Another element of the data sheet to bear in mind is the working temperature range, that is the operating temperature range within which the load cell can in any case work without breaking, but it does not guarantee its methodological characteristics.

→ Read also How to choose a load cell? Technical features guide to find out more about: protection rating, construction materials, thermal compensation and working temperature range.

Will the load cell be used in an area with potentially explosive atmosphere?

❖ If we have to install the load cell in an area classified as a place with a risk of explosion due to the presence of mixtures of gas, vapors or flammable mists or combustible powders, targeted certification will be essential.

The most suitable certification will depend both on the classification of the hazardous area and on the market where the application is installed.

The load cell will then have to be certified on the basis of the regulations in effect in the country of reference, for example:

- ATEX regulations for the European Union

- IECeX certification scheme at the international level,

- FM HazLoc certification for the United States and Canada

- EAC Ex certification for the countries of the Eurasian Customs Union

- Ex NEPSI certification for the People's Republic of China

→ See all our products for explosive atmospheres

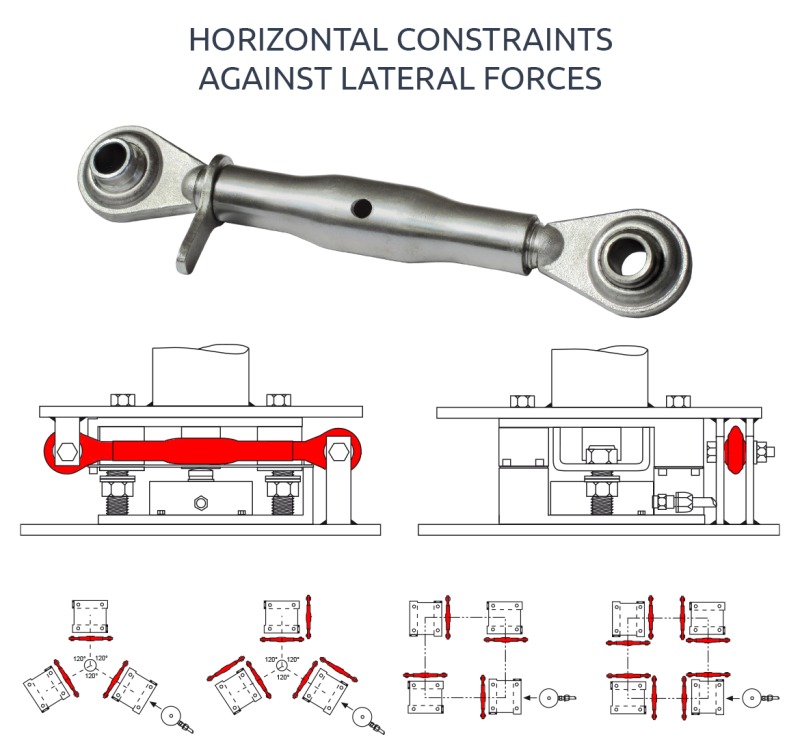

Is the installation area classified as seismic? Or is it an especially windy area?

❖ All conditions that can generate extraordinary vibrations or forces must be considered for questions of both safety and accuracy and precision of the weighing.

In these cases it is necessary, already at the time of purchasing the load cells, to make provision for accessories, mounting kits and adequate constraints that can ensure proper installation able to protect it from any potentially damaging stresses.

Sometimes the standard mounting kits might not be sufficient for the purpose; in these cases it will be the job and responsibility of the plant designer to make provision for, calculate and install specific anti-tilt constraints supporting the weighing system.

LAUMAS Tenditore300, a horizontal constraint against sideways movement.

→ Watch the tutorial Constraints against horizontal forces and tilting

2. HOW DO WE WEIGH?

Assessing the specific application of the weighing system.

An analysis of the type of application in which we will need to install the weighing system gives us precise information on the load cell to use.

What application is it? How does it work, or rather what is the method of loading?

❖ Based on the very operation of the plant we will first of all know whether a compression load cell or a tension load cell will be needed.

❖ Depending on the particular type of application then, we will orient ourselves within the many types of load cells available.

Certain applications are so specific as to require only one particular model of load cell.

This is the case, for example, of load cells for wire rope measuring when they work as load limiters in lifting systems or that of anchor load cells applied to measure and monitor the tensioning force of tie-beams in civil works.

Another example is the load cells for foot brake, specifically conceived to measure the force exerted by the foot on a car’s brake pedal.

→ Read also The main types of load cells

Application of an anchor load cell.

Does the type of application require observing stringent hygienic requirements? Will the load cell be washed with chemical detergents?

❖ For applications requiring observance of particular hygienic requirements we will definitely opt for a load cell made of stainless steel with an adequate IP rating (IP69K), to protect it from washing with water at high temperature and pressure and from the aggressive action of chemical detergents.

❖ Sometimes, in certain sectors such as the food or chemical-pharmaceutical sector, it is necessary or anyway desirable for the load cell to have a specific certification, which attests to it being perfectly sanitizable.

The international certifications to be referred to are the 3-A Sanitary Standard or EHEDG.

The LAUMAS hygienic load cell for foot, model FLC3A.

What are the hygienic requirements of the FLC 3A load cell for foot?

Are there any mechanical constraints?

❖ If there are problems of space in the application to which the load cell has to comply with, the more or less compact dimensions of the sensor can be a discriminating factor to consider.

Does the application include the risk of accidental impacts, shocks, overloading or unbalanced loads?

These factors are decisive especially in the choice of the capacity (or rated load) of the load cell.

❖ To determine this, as a matter of fact, it is not enough to know the gross weight, that is the overall weight on the load cell, but it is also necessary to consider whether the type of application entails the risk of impact, vibration, excess load on one side, material loading or unloading…these are all situations that introduce additional forces (also called “parasitic forces”) that act on the load cell not only in the main direction for which it was designed, but also on the side, from underneath or from another direction.

These forces risk damaging the load cell if its capacity is too low, but also altering the measurement results of the load cell itself.

Impact between a forklift truck and a roller conveyor.

To be sure that the load cell will work properly and provide reliable results also under these conditions, it will then be necessary to oversize its capacity.

❖ It is also important to make provision for a proper installation with the aid of appropriate accessories mounting kits, which act as anti-tilt constraints and constraints against sideways movements.

3. WHAT DO WE WEIGH?

Assessing the object of the weighing system.

How much do the goods weigh and what are their dimensions? Is the load static or dynamic?

❖ The object to be weighed also gives us information about the capacity the load cell will need to have.

Factors such as the dimensions and weight of the goods, as well as whether it is a static or dynamic object, together with the weight of the structure itself and the possibility that parasitic forces might come into play, help define the maximum load contemplated during the measurement.

It will be necessary to make sure that the load cell has a sufficient capacity to handle it.

FOCUS:

As a rule it is always recommended to oversize the load cells in relation to the maximum load to be applied to the weighing system, choosing them with a rated capacity at least 25 – 30% higher. For some applications it could be necessary to oversize them by as much as 100% or more.

→ Read also How to choose a load cell? Technical features guide to find out more about the capacity of load cells.

Do we have to weigh explosive substances?

❖ The type of goods to weigh can also affect the classification of an area as potentially explosive atmosphere: this is the case of weighing in petrochemical plants or generally plants with explosive substances, including powders and flours.

In these cases, too, we will take into consideration load cells with the most appropriate certifications (ATEX, IECEx, Hazloc, EAC Ex, Ex NEPSI etc.)

What is the value of the goods we have to weigh?

❖ The object to be weighed also affects the analysis of the degree of accuracy that must or may be obtained.

A medical scale that has to batch the active ingredients of a pharmaceutical product, for example, needs greater accuracy than an application weighing large quantities of building material.

In general, low-value goods (such as sand or gravel) do not need particularly precise weighing, while in applications for pharmaceuticals and for more significant products the weighing system needs a high level of accuracy.

In any case, for medical or legal applications or ones that entail calculating a price, it will be necessary for the load cells to be certified in accordance with obligatory regulations that establish the required degree of accuracy, even stringently.

In the following section we will be analyzing the main parameters to be taken into consideration for defining the degree of accuracy of a load cell: OIML R 60 certification and OIML accuracy class (also called “precision class”), combined error, resolution and the effect of temperature changes.

4. WHY DO WE WEIGH?

Assessing the purpose of the weighing system.

Different jobs require different performance of the load cells.

The weighing system can have the ultimate purpose of batching, load limitation for reasons of safety, checking quality or counting pieces of a production (piece-counting function), in-line weight checking system, statistical check on prepackaged goods or to establish a price.

Other times the purpose of the system may be to measure and monitor the force and not the weight, for example in the geotechnical sphere or in a material test machine.

In-line weight checking system.

What degree of measuring accuracy is required of a load cell in the context of its specific application and in relation to its purpose?

Analyzing the tangible job of a given weighing system allows us above all to assess what degree of accuracy and precision the weight measurements have to guarantee.

Some applications require a very high one, while others can tolerate slightly lower performance.

❖ Accuracy and precision might not have too much importance, for example in a lifting system in which the load cell has the sole task of limiting the maximum load applied, with more of a safety function than actual weighing.

❖ On the contrary, they are fundamental requirements of a load cell when the weighing system is finalized at legal for trade use, that is when the purpose of the weighing is to determine a price of sale for a commercial transaction.

In this case the load cell must necessarily be approved, that is have the OIML R 60 metrological certification attesting observance of strict metrological requirements defined by the International Organization of Legal Metrology (OIML), guaranteeing the high quality of the load cell in weighing.

This certification is required for applications approved in many countries, including the European Union and the United Kingdom.

→ See our OIML R60 approved load cells

Depending on the market for the load cell, other similar certifications may be useful, which certify how the sensor meets the metrological requirements required for legal for trade use by the regulations of many countries, for example:

- NTEP certification for the United States

- PAC (Pattern Approval Certificate) for the Russian Federation

- CPA (Chinese Pattern Approval) certification for the People's Republic of China

❖ Other characteristics to be considered, especially when the application requires a high level of quality of the measurement result, are:

- OIML accuracy class / legal divisions.

This is the classification, depending on the OIML R 60 certification, that describes the methodological characteristics of the load cell and indicates their degree of accuracy and precision.

The different classes are marked by a letter expressing their level of accuracy (A, B, C and D) and by a number specifying how many legal divisions the load cell is able to measure in units of thousands.

Legal divisions are the smallest certain weight changes, stable under all conditions of measurement, that the load cell is able to measure.

More legal divisions means greater measurement accuracy since they permit detecting smaller weight changes.

For example, the C3 accuracy class indicates that it is a load cell that can be installed in weighing systems capable of measuring weight changes of down to 1/3,000 of the system's maximum capacity.

Class D1 therefore denotes less accuracy, acceptable for example for a load cell used for weighing construction material, while from class C3 up to C6 and beyond there are highly accurate load cells, suited for precision scales, checkweighers, approved weighing systems, bench scales and weighbridges. - Combined error.

Expressed as a percentage of the full scale, this value represents the maximum error that can be expected of a load cell.

The characteristics of linearity, hysteresis and temperature error are verified in OIML tests in a single set of tests that give an overall limit to the sum of the three errors measured.

This value is the combined error. The lower it is, the more it indicates that the load cell is accurate and precise. - Minimum verification interval (V min).

This is the minimum verification interval into which the load cell measurement range can be divided.

It is obtained from the ratio between the maximum capacity of the load cell and the value Y (or relative V min) established by the OIML tests.

It actually describes the resolution of the load cell, that is the minimum increase in weight that the load cell is able to measure.

This value is essential when the load cell has to be used in a weighing system approved for legal for trade use. - Effect of temperature changes.

The effect of temperature on the zero and the effect of temperature on the full scale indicate exactly the maximum error that an increase or decrease in temperature causes to the reading of the load cell, that is by how much the zero or full scale value can differ from the actual value as a percentage of the full scale for each degree centigrade in temperature change.

→ Read also How to choose a load cell? Technical features guide to analyze these parameters

❖ In addition to all the discriminating factors analyzed so far, in order to choose the most appropriate load cell you also need to consider:

- the economic factor: load cells vary considerably in terms of cost, depending on the specifications, therefore it is necessary to bear in mind your budget too.

- A careful study of how the load cell will need to be installed.

Planning and making a correct installation of the load cell is decisive in order to obtain the best performance from the sensor and ensure its safe and long-lasting use.

→ Read also How to install a weighing system correctly or watch the tutorial:

Guidelines for the correct installation load cells, weight indicators and weight transmitters

In conclusion: the choice of the right load cell for a given application lies in the complex assessment and in the interplay of all the factors we have examined.

LAUMAS assists its customers in this activity of preliminary analysis, offering all its experience.

We can help you in the choice of the perfect load cells for every specific requirement and advise you with regard to the most suitable assembly for their application.