How to choose a load cell? Technical features guide

Read and understand the data sheet

In order to choose the most appropriate load cell for your weighing system, you need to bear in mind many factors: from the type of application (the characteristics of the structure to be weighed, it operation, the purpose and the object to be weighed) to the ambient conditions where the system will be working.

After identifying the most appropriate load cell model, it is important to understand its data sheet, which describes all its features and gives all the data for making a decision.

But what are the main features of a load cell and what do they tell us about its performance?

→ Read also How to choose a load cell? The factors to assess.

→ Read also The main types of load cells.

Certifications

A certification is a document attesting thet a certain product meets a set of internationally standardized technical and construction rules and regulations and is issued by an official organization.

The choice of the certifications that a load cell needs to have is made based on the market, environment and type of system in which the load cell will have to work.

In LAUMAS offer there are several to evaluate, depending on the type of certification and the regulations of the country in which the load cell is to be installed.

▷ Certifications for legal for trade use.

OIML R 60 - a foundamental metrological certification for legal for trade use, which certifies load cell measuring quality. It divides load cells into accuracy classes and certifies the legal divisions and the level of accuracy of the sensors. It's required for applications approved in many countries, including the European Union and the United Kingdom.

NTEP - compliant with the regulations of the United States.

PAC (Pattern Approval Certificate) - compliant with the regulations of the Russian Federation.

CPA (Chinese Pattern Approval) - compliant with the regulations of the People's Republic of China.

▷ Certifications for use in potentially explosive atmospheres.

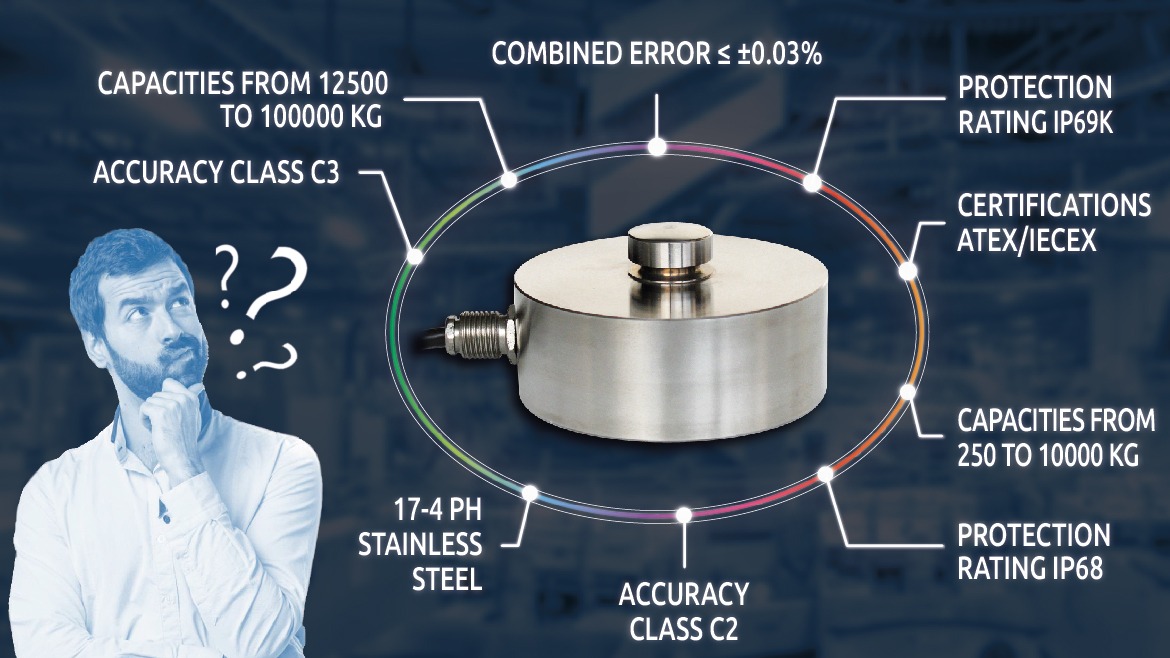

ATEX and IECEx - ATEX certification is valid in the European Union, while IECEx certification is recognized in over 30 international markets.

EAC Ex - for use in the countries of the Eurasian Customs Union.

FM HazLoc (Hazardous Locations) - compliant with the regulations of the United States and Canada.

Ex NEPSI - compliant with the regulations of the People's Republic of China.

→ Explore all products for potentially explosive atmospheres.

▷ Certifications for use in environments where hygiene is a necessary or important requirement.

3-A Sanitary Standards - american standard that regulates the design, production and use of hygienic equipment, for protecting the end product from the risks connected with contamination and bacterial proliferation.

Do you want to know the new LAUMAS hygienic line?

▷ Certifications and markings necessary for exports to different countries.

CE - European conformity mark that certifies the product's compliance with all the EU regulations throughout its entire life cycle: from design to maufacture, placement on the market, putting into service and finally disposal.

UKCA (UK Conformity Assessed) - this is the conformity mark for the United Kingdom introduced in 2022 after Brexit. It is the equivalent of the European CE marking and can be used for putting products on the market of Great Britain (England, Wales and Scotland).

EAC - certification for export to the countries of the Eurasian Customs Union.

Depending on the product category and the regulations applied, CE and UKCA are not obligatorily substantiated by a certificate. To certify that the product is compliant, the marking and the declaration of conformity are sufficient, which can be done completely by the manufacturer or by the subject that puts the product into the European Union.

Material

The materials of which a load cell can be commonly made are:

- 17-4 PH STAINLESS STEEL

- AISI-420 STAINLESS STEEL

- ALUMINIUM ALLOY

- SPECIAL NICKEL-PLATED STEEL (AISI 4140 or AISI 4340)

▷ 17-4 PH STAINLESS STEEL

Among the various materials used for load cells, this is the most "valuable" one, the most costly and the best one for corrosion resistance.

Its official name is AISI 630, but is commonly called 17-4 PH from its "technical" definition. It is in fact composed of 17 parts of nickel and 4 parts of chromium, while PH is the abbreviation of Precipitation Hardening, that is the process of precipitation used for hardening the material.

Precipitation hardening (or age hardening) is a thermal treatment that takes place in an oven and goes through 3 stages: solubilization, tempering and aging. The process ensures that, through the controlled release of the elements, precipitate aggregates are formed that produce an increase in hardness.

→ Read also How is a load cell made? to know about all its construction stages

▷ AISI-420 STAINLESS STEEL

Even though its corrosion resistance is lower than that of 17-4 PH stainless steel, it has greater mechanical strength and is more economical.

▷ ALUMINIUM ALLOY

The AVIONAL type is the typically used, that is the one used to make aircraft and aviation components.

It is very useful in single point load cells because it has good resistance to environmetal agents. It is also light and easy workable, even in the final finishes that are necessary for this type of cells.

▷ SPECIAL NICKEL-PLATED STEEL (AISI 4140 or AISI 4340)

AISI 4140 and AISI 4340 are two very similar materials and are actually interchangeable.

They are called "special steels" because they have special characteristics. They are in fact admixed with substances such as, for example, chromium, nickel, molybdenum and manganese that improve their quality compared to iron alone and they are always nickel-plated, otherwise they oxidize immediately.

→ Read also How to choose a load cell? The factors to assess to determine the most suitable material for your application.

Nickel-plating (like zink-plating) is an operation that is generally called galvanization or galvanic coating, that is the process of coating one metal with another metal.

The process than takes on a specific name depending on the material being used.

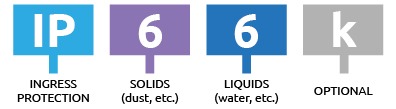

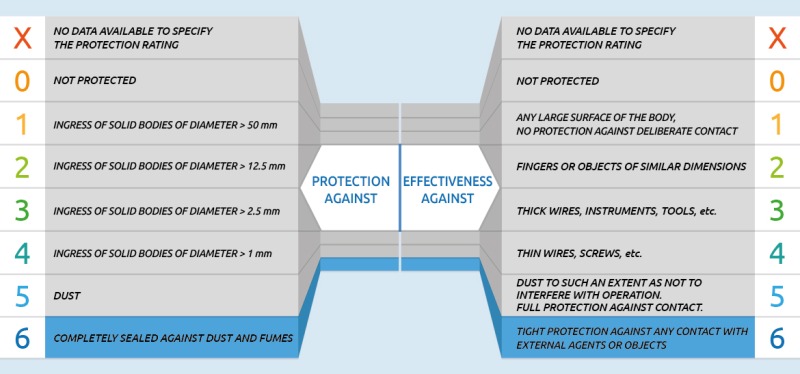

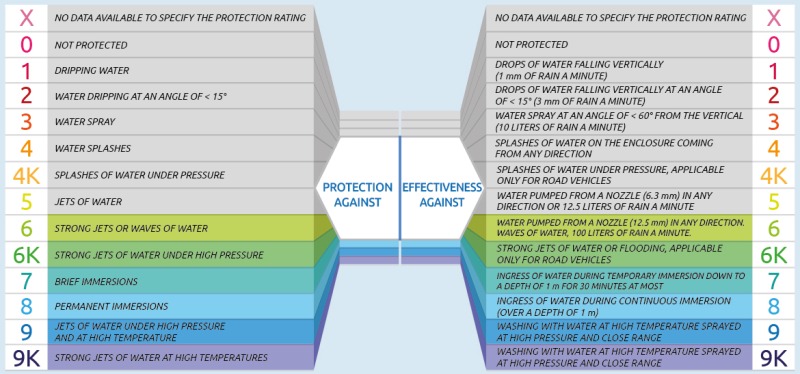

Protection rating (IP)

This parameter classifies the level of resistance and tightness of electrical enclosures against the ingress of objects, dust and water. It is defined by the international standard IEC 60529 and corresponds to the European standard EN 60529.

Although IEC 60529 is a valid standard at the international level, it is chiefly used in Europe and Asia. Other standards instead prevail in other countries: USA, Mexica and Canada for example prefer the NEMA 250 standard.

It is essential to choose the protection rating according to the environment where the load cell will have to work. Protection requirements in fact differ depending on the place (indoor or outdoor) and ambient conditions where the system is to be installed, the frequent or occasional washing the load cell will be subjected to and the methods used, as well as whether it will have to be immersed, to what depth and for how long.

It is indicated by the acronym IP (Ingress Protection) followed by 2 digits and possibly by the letter K.

If the digits are replaced by the letter X, it means that there are not enough data available to specify the protection rating.

▷ The first digit in the code indicates the protection rating of the device against the ingress of solid objects and the possibility for people to have deliberate contact with hazardous parts, such as, for example, the electrical conductors.

The value can range from 0 to 6, where 6 indicates an enclosure completely sealed against dust and fumes with full protection against contact.

▷ The second digit instead indicates the level of protection against the ingress of liquids and moisture ranging from 0 to 9. If the digits is followed by the letter K, it means that the component is protected against the ingress of water during high-pressure water jet cleaning.

Nominal load (capacity)

Also called "nominal load", the capacity is the maximum weight that the load cell can withstand.

Every type of sensor is born with its specific capacity range. Capacity is a constraint of a mechanical nature that is predetermined on the engineering drawing of each load cell.

→ Read also How is a load cell made?

▷ Low-capacity load cells weigh from a few grams up to a maximum of 100 kg.

They are perfect when great accuracy is needed, such as for laboratory scales or piece-counting scales.

▷ Medium-capacity load cells can measure from 100 kg to approximately 10 metric tons.

They are especially reliable and are used for making industrial weighing platforms and for weighing belts, roller conveyors, hoppers, silos and tanks of small and medium dimensions.

▷ High-capacity load cells instead reach up to over 1000 metric tons.

They are used for building weighbridges, for heavy industry and generally in scales that have to weigh large loads, such as, for example, high-capacity silos.

For all capacities, even non-standard ones, it is possible to request custom load cells, to your own design and specifications.

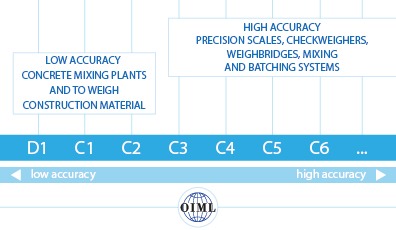

Accuracy class

Accuracy classes (or precision classes) are group classifications determined by the International Organization of Legal Metrology (OIML).

They describe the metrological characteristics of the load cell and are fundamental in determining the level of quality of the measurement result.

For each type of load cell there is a different OIML classification indicated by a letter identifying their level of accuracy (A, B, C, D) and by a number specifying how many legal divisions the load cell is able to measure in units of thousands:

- D1, C1, C2: low accuracy, the load cells can be used in concrete mixing plants to weigh construction material such as concrete, sand, cement or water.

- C3, C4, C5, C6 and higher: high accuracy, suited, for example, for precision scales, checkweighers, weighbridges, CE_M APPROVED weighing systems, mixing and batching systems.

The issuing authorities (OIML Issuing Authorities) and the organisms notified by the European Union are authorized to assess load cells and assign the related accuracy class.

Certificates issued by the issuing authorities are valid worldwide, while those of the notified organisms are valid only within the European Union.

The assessment is made through a test measuring 3 variables simultaneously: linearity, hysteresis and the effects of temperature, verifying the combined error of the load cell.

Linearity

This checks the proportionality for increasing load values in a load cell.

Load tests for increasing points give straight line joining the zero point and the full-scale point.

It is then verified by how much the values actually read by the load cell differ from this line.

The distance is the linearity error.

Hysteresis

This is the assessment of the difference between the load cell response during a load cycle and a subsequent unload cycle.

The percentage difference is calculated between the same points read by the load cell during the two cycles which gives the hysteresis error.

Effects of temperature

The load cell is placed in a climatic chamber. After stabilizing the temperature, in a standard range defined by OIML between -10 °C and + 40 °C, 3 load/unload cycles are run for each temperature.

After ending the test, it is seen by how much the averages of the values measured, as the temperature changes, deviate from the maximum permitted errors.

The appropriate accuracy class should be chosen by taking into consideration multiple aspects of the weighing system, such as the type of plant, the purpose and type of the goods to weigh, and it is often a compromise between them.

The capacity of the weighing system also plays a fundamental role.

It is in fact necessary to asses the right match between the desired accuracy an the system's capacity.

→ Read also How to choose a load cell? The factors to assess.

Combined error

This is the sum of the 3 errors (linearity, hysteresis and effects of temperature) from the OIML test described in the previous section.

This figure, expressed as a precentage of the full scale, represents the maximum error that can be expected of a load cell.

For example, from a load cell with a 10000 kg full scale and a combined error equal to 0.05%, one would expect a maximum error of 5 kg throughtouts its scale of measurement.

If the weight reading should be 2500 kg, the "real value" would then be between 2495 and 2505 kg.

Minimum verification interval (V min)

This is the minimum interval ito which the load cell measurement range (its capacity) can be divided.

It is obtained from the ratio between the maximum capacity of the load cell and the value Y (or relative V min) established by the OIML tests.

It actually describes the resolution of the load cell, that is the mimimum insrease in weight that the load cell is able to measure.

This value is essential when the load cell has to be used in a weighing system approved for legal for trade use.

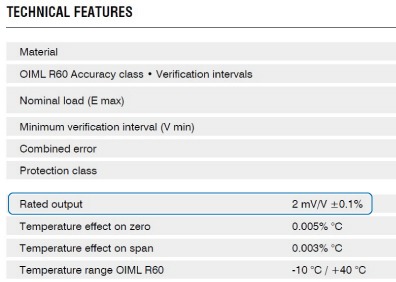

Rated output

The rated output, expressed in mV/V, is the output value in mV thet the load cell returns when the maximum load is applied, divided by the power supply voltage in V.

The value we find on the data sheet is the one that observes this condition, while the percentage value alongside is the value of uncertainty (hoe much the output value will oscillate ± as a percentage) and is specified directly by the builder.

Effect of temperature on the zero and full scale

This is the error that an increase or decrease in temperature causes to the reading of the load cell, that is by how much the zero or full scale value can differ from the actual value as a percentage of the full scale for each degree centigrade in temperature change.

If, for example, a load cell has a full scale equal to 1000 kg and the effect of temperature on its full scale is 0.005% FS/°C, for each change in °C the reading can vary by at most 0.05 kg.

If the temperature then varies by 10°C (for example it changes from 20°C to 30°C) the reading will vary by at most 0.05 x 10, that is 0.5 kg.

Thermal compensation

This is the temperature range within which the load cell can work observing the temperature errors reported under "Effect of temperature on the zero and full scale".

Load cells are in fact tested and thermally compensated at different temperatures precisely to ensure accuracy and adequate preformance. The standard thermal compensation temperature range is between -10°C and + 40°C.

Working temperature range

This is the temperature range within which the load cell can work without breaking, but in which the performance stated on the data sheet is no longer guaranteed.

Creep at nominal load (after 30 min)

The value of creep, or "viscous flow", is the capacity of the load cell to offset the natural creep of the material of which it is composed. In practice, when a constant load is applied to it under stable ambient conditions, the reading of the load cells will not change or will change very little.

The value stated on the data sheet is the possible percentage change in the full scale (in kg or in mV/V) after 30 minutes of application of the nominal load.

A lower creep percentage tranlates into a better quality of measurement of the load cell. It is, in fact, fundamental for the "creep at nominal load" value to be low, since this contributes to the stability of the measurement over time.

This parameter moreover affects the elastic properties of the load cell. After applying a weight, the lower the creep value, the faster the zero signal will return to the initial condition (load cell with no load).

How is the creep test done?

The load cell is loaded to the full scale value for 30 minutes and, for the entire duration of the test, the weight reading must not exceed an error determined by the OIML R 60 standard.

At the end, the percentage ratio between the change in reading of the weight and the theoretical full scale throughout the 30 minutes of the test gives the creep at nominal load.

Maximum tolerated power supply voltage

This indicates the maximum power supply value in V that the load cell can withstand.

The weight indicators and weight transmitters usualli have a standard power supply value of 5VDC or 10VDC, specifically conceived to be perfectly tolerated by the load cell.

It is also possible to use non-standard power supply devices, but it is essential for them to observe the maximum power supply voltage stated on the data sheet so as not to damage the load cell.

Input/output resistance

The input resistance is the resistance measured in Ohm between the power supply wires of the load cell. The output resistance is conceptually identical to the input resistance, but it measured between the load cell output signal wires.

Their value depends on the type of strain gauge used, but is tipically between 350 and 400 Ohm or between 700 and 800 Ohm.

Zero balancing

This is the value, expressed as a percentage of rated output, that defines by how much the output value in mV can deviate from zero with no load.

Insulation resistance

This defines the quality of the insulation between the single wires of the load cell and the body of the load cell and between the cable shield and each wire of the load cell.

Correct insulation makes the measurement made by the load cell insensitive to changes in electrical potential or electrical charges in the body of the load cell.

Maximum static load

Expressed as a percentage of the full scale, it is the amount of overload the load cell can withstand without getting damaged, that is its "yield strenght".

If the overload value remains under the reccomended percentage, which is normally between 120% and 150% of the full scale, the load cell retains its elasticity (its capacity to deform and return to zero). If it exceeds the recommended percentage value, the load cell will permanently deform and then be broken or damaged.

Breaking load

Expressed as a percentage of the full scale, it is the maximum load the load cell can withstand without breaking.

This value depends on the geometry, the material and the type of load cell and theoretically should never be reached, but it is in any case important to know it especially when having to make calculations on the cofficient of safety of the plant.

For example, in lifting and load limiting systems, which require a high safety coefficient, it is necessary to make sure that the load cell used has a greater breaking load than the standard one, which is usually between 250% and 300% of the full scale.

→ Read also The main type of load cells: characteristics and applications.

→ Read also Weighing systems and load limiters for bridge cranes.

Deflexion at nominal load

This indicates how much the load cell deforms at full scale, that is how much the load lowers when applied on the load cell.

This value is different for each single load cell, but always comes within a range of between 0.2 mm and 1 mm.

Example of deflection at nominal load of 0.5 mm in an AZL load cell.

Electrical connections

This part of the data sheet refers entirely to the load cell output cable.

Besides the details such as its lenght and diameter, it also states the number of wires of which it is composed and the size of its cross-section in mm2.

Load cells typically have 4 or 6 wires. The difference lies in whether there are 2 wires called "reference wires" (Sense + and Sense -), which are used to improve measurement accuracy.

Thanks to the reference wires in 6-core cables, the load cells can offset any change in voltage drop on the cables due, for example, to changes in temperature or cable lenght, without this affecting weight measurement.

The 4-wire load cells, on the other hand, are calibrated and thermally compensated in relation to the lenght of the cable with which they are supplied as standard, which is why the cable lenght should not be altered.

In 4-wire load cells, in order to limit a voltage drop in the portion of the cable between the junction box and the weight indicator, it is enough to use a shielded cable with a significant cross-section (at least 1 mm2).

→ Read also How to install a weighing system correctly, to know the other regulations to observe.