What a load cell is and how it works.

Let's find out how it’s made and how it measures weight force.

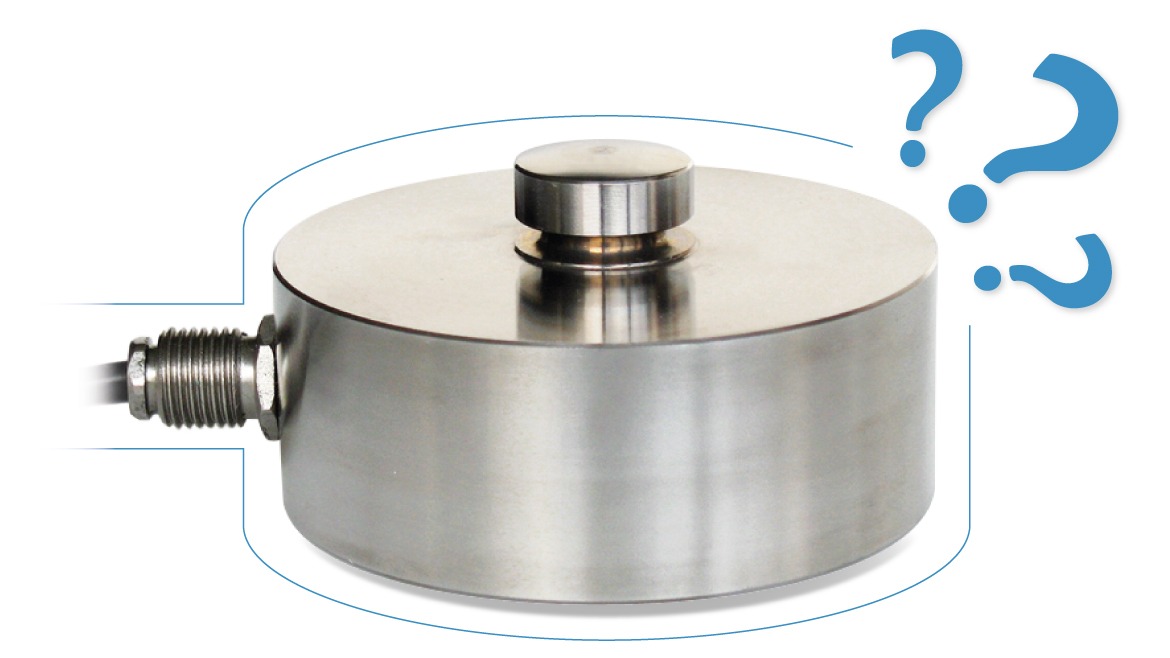

Strain gauge load cells are sensors used to measure weight force. They are generally used in weighing systems or in systems for measuring force, compression and tension.

The force applied to the load cell is read by measuring a mechanical deformation that the sensor converts into an electrical signal in mV, proportional to the deformation.

But exactly how does a load cell work?

How it is made

To understand how a load cell works it is first of all necessary to consider how it is made.

A load cell is composed of two parts: a mechanical body and an electric circuit.

The body supports the weight or force applied on the sensor.

It is generally made of high-grade steel or aluminum. These are strong but also elastic materials capable of undergoing a slight deformation under load and returning to the initial position, responding to the stress.

These materials therefore ensure mechanical reliability and an even distribution of the deformation.

This mechanical characteristic is called resilience: the higher it is and the greater is the material’s capacity to absorb energy and deform without however the deformation being permanent.

The body of the load cell contains strain gauges, electrical conductors composed of very thin metal wires of constantan arranged in a grid with a tight zig zag pattern and applied onto a film of insulating material.

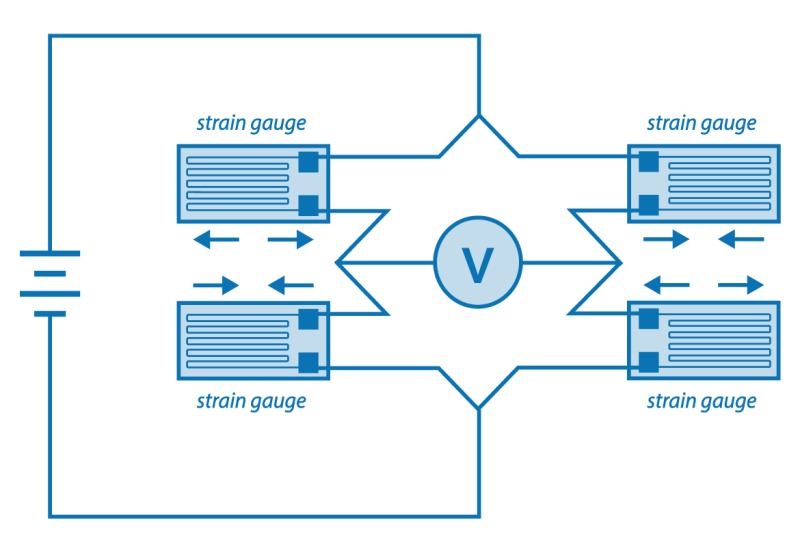

The strain gauges are securely glued in the area of greatest deformation of the body of the load cell and are connected together in a Wheatstone bridge circuit.

The combination of mechanical housing and strain gauges forms a load cell.

→ Read also How is a load cell made? to get to know the details of the manufacturing process.

How it works

When a force is applied onto a load cell, it flexes slightly: the metal deforms and then returns to its original shape once the load is removed.

The strain gauges, entirely integral with the body of the load cell, deform together with its surface, stretching or contracting.

These slight variations in size, expressed in thousandths of a millimeter (micrometers or microns), cause a change in the electrical resistance of the conductors that form the strain gauges: when a conductor is stretched, its resistance increases; when it is compressed, its resistance decreases.

Example of a complete Wheatstone bridge on a bending beam load cell.

The change in resistance is measured and converted into a proportional signal expressed in mV, through the connection of the strain gauges in a Wheatstone bridge.

In the case of an analog load cell, the signal in mV of the load cell is processed by a transmitter or by an external weight indicator, which converts it into a digital signal and displays it as a value of weight.

In the case of a digital load cell, this conversion takes place directly inside the load cell itself.

Lastly, the weight value can be transmitted to a PC or PLC through an analog output or a fieldbus.

Different types of load cell

Load cells, whose composition and basic operation we have briefly seen, are extremely versatile sensors.

In fact, they offer accurate performance in a great many different applications and are essential in many sectors:

- industrial automation and automotive;

- chemical-pharmaceutical, livestock and food industry;

- building, lifting systems, packaging, textiles and paper;

- transport and handling

- retail (scales for selling by weight).

Depending on the specific applications, load cells are designed with shapes, dimensions and characteristics that can even be very different to each other.

→ Read also The main types of load cells

→ Read also How to choose a load cell? Technical features guide

→ Read also How to choose a load cell? The factors to assess