W-series weight indicator programs: features and operation

Which operating programs can be activated on the LAUMAS W-series weight indicators and how to choose the most suitable one.

LAUMAS W-SERIES weight indicators have several operating programs (firmware) available that can be installed on the instrument according to different needs.

How to choose the right program to use?

Here are the key features of each one and when to use them.

BASE

This is the simplest program and is installed by default on our weight indicators.

It allows set-point values to be set freely, but does not have specific automatic batching functions.

It is ideal in situations where the instrument simply needs to display the weight and put it at the service of the weighing application in which it is installed.

Weight indicators with base program can be connected via fieldbus or analog output to the PLC that manages the automation of the machine or system on which the weighing system is installed.

How does it work?

First, you set the set-point values (thresholds) and the hysteresis value, if any.

When the weight reaches or exceeds one of the programmed set-point values, the corresponding relay contact changes state.

Once the weight returns below the set-point value (minus the hysteresis value, if any), the relay contact returns to its initial state.

With the BASE program, it is possible to carry out also manual or semi-automatic batching, thanks to the NET/GROSS function, using the corresponding external input or the TARE button on the weight indicator.

This button is used to toggle between the two states and to display both the net weight of the product in the phase of batching and the gross weight present on the system.

RIP

The RIP program transforms the instrument into a serial remote display that displays the weight value transmitted by a second weight indicator that is actually connected to one or more load cells.

It is useful for displaying the same weight measured by a single weighing system on two different instruments.

On the instrument working as a remote display, you can determine which type of weight is displayed (gross or net) and you can set setpoints to pair with the digital outputs.

LOAD

This is the single-product load batching program, for automatic batching applications.

It is used in processes where the weighing system has to be loaded with only one product and allows the instrument to manage the batching sequence.

How does it work?

The program provides a set of 99 user-programmable formulas.

To start batching, select one of the programmed formulas, specify the number of cycles to run and press the START button.

If the system is managed via a PC or PLC, starting can be automated.

When the cycle is finished and the product has been weighed, the weight indicator saves the consumption, i.e. the quantity of batched product, sends the batching data to the printer or saves it on a USB stick.

It closes the cycle end contact and starts the unloading phase.

As soon as it reaches the minimum weight value and the safe emptying time has elapsed, the cycle end contact re-opens.

The weight indicator is now ready to receive a new START command.

If more than one cycle has been programmed, the program restarts automatically.

UNLOAD

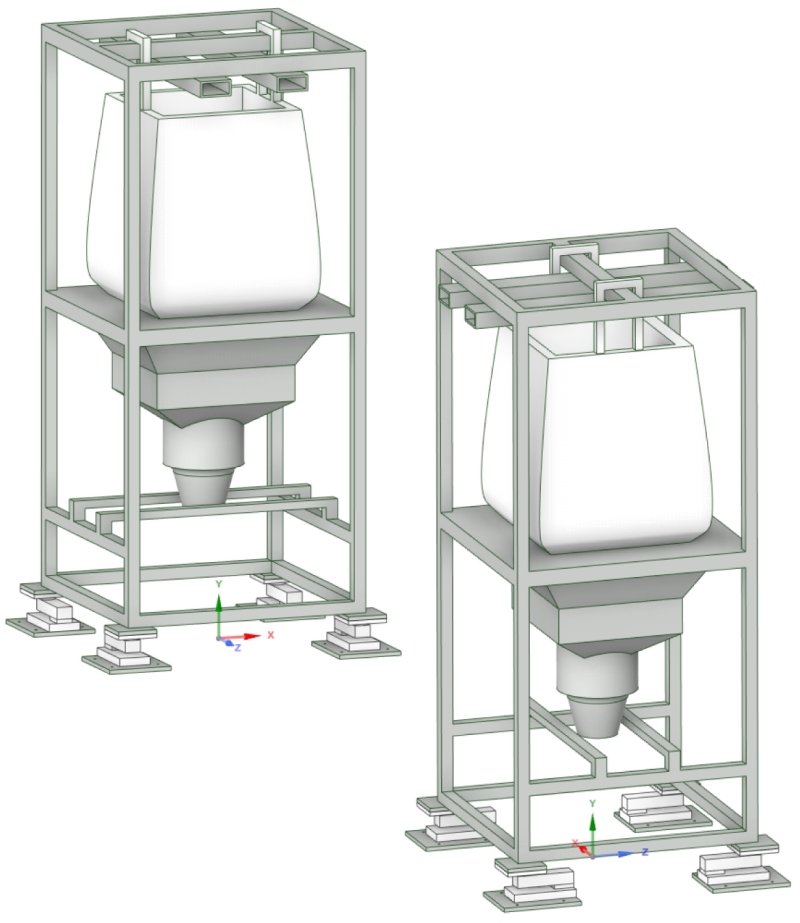

This is the single-product unload batching program, for automatic batching applications.

It is used in processes where a predetermined quantity of product has to be batched, automatically extracted from the weighing system.

It is useful for example in big bag emptier machines, among other functions also to keep in memory the remaining part of product to be batched when unloading once the big bag has been completely emptied and has to be replaced with a new one (big bag emptying function).

How does it work?

The operator programs one of the 99 available formulas, selects it, specifies the number of cycles to run and lastly starts batching by pressing the START button.

If the system is managed via a PC or PLC, starting can be automated.

The instrument checks that the weight in the machine is greater than the quantity to be extracted, after which it automatically tares and shows the increasing weight of the unloaded product on the display.

When the cycle is finished and the waiting time has elapsed, the display will again show the weight in the weighed system. It then saves the consumption (the quantity of batched product), closes the cycle end contact and sends the batching data to the printer or saves them on a USB stick.

It is now ready to receive a new START command or to restart automatically if more than one cycle has been programmed.

3/6/14 PRODUCTS

This is the multi-product batching program, for automatic batching applications.

It allows the weight indicator to manage the batching sequence of a mixture of products automatically loaded into the weighing system.

It is useful, for example, for batching the ingredients used for making concrete.

How does it work?

They program the batching formula (from the 99 available ones), the order of the products to be weighed and the number of cycles to run.

After selecting the programmed formula, the operator can start batching by pressing START.

If the system is managed via a PC or PLC, starting can be automated.

The instrument starts batching the formula starting from the first selected product.

Once the first product has been batched and the waiting time has elapsed, it saves the consumption, displaying the net weight, and proceeds to batch the next product.

It does the same thing for all the products, until the end of the cycle.

When the last product has also been weighed, it saves the consumption, closes the cycle end contact and the unloading phase begins. It waits until the minimum weight is reached and allows the safe emptying time to elapse. It then sends the batching data to the printer or saves them on a USB stick.

If more than one cycle has been programmed, batching will restart automatically.

Specific external relay modules are required for the 6 and 14 product batching programs to function correctly:

- RELE6PROD for the 6 product program.

- RELE6PROD and RELE14PROD for the 14 product program.

MULTI

It includes all the previous programs.

It is useful for vendors who decide to keep in stock weight indicators whose final application is not yet known: the installer will be able to select the type of software they want, depending on the specific application.

With MULTI-program weight indicators, the vendor will then have “wildcard” instruments at hand to adapt to the different supply needs that will be required.

You can watch the LAUMAS W-series weight indicators webinar recording for a complete overview of the main features, functions and uses of these instruments.