Weighing and dosing system on agricultural machinery

Integration of a weighing system on fertilizer spreader machines.

Requirement

SAM Machinery requires real-time weighing and dosing of the load on a moving fertilizer spreader during field operations.

The weighing system must operate in challenging agricultural environments, subject to dust, vibration, and moisture. It must also be compact to adapt to the moving machine and integrate flawlessly with the control system.

SAM Machinery is a New Zealand-based manufacturer of high-performance agricultural equipment that integrates classic machinery with smart technologies.

Our solution

For the weighing system on the spreader, we used:

- 8 FTP stainless steel shear beam load cells, 5,000 kg capacity;

- 1 TLM8 CANopen multichannel weight transmitter.

How does it work?

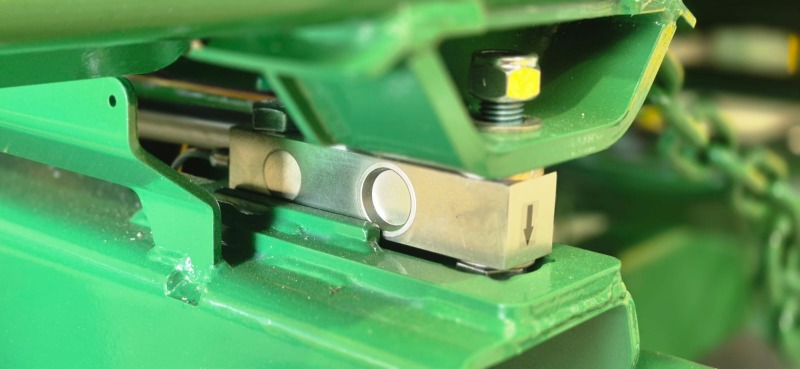

Each fertilizer spreader features a custom frame with 8 FTP IP68-rated 5,000 kg load cells.

Each load cell is installed at key weighing points under the hopper and connected directly to the TLM8 weight transmitter.

The weight transmitter is mounted in a box on a custom Omega/DIN plate, which is mounted on a rubber support next to the hydraulic and electrical systems.

The load cells detect the weight of the product inside the spreader in real-time and the weight transmitter communicates the data via CANopen protocol to the control unit.

The operator sets the desired product flow rate through the control unit, which then adjusts the product realease in the field based on the machine's ground speed.

The weighing data is also used to alert the operator about the remaining product quantity and the total product distributed.

The added value

- FTP load cells are compact and integrate seamlessly with the machine frame, minimizing space requirements.

- The TLM8 weight transmitter with 8 independent channels monitors and manages individual load cells, facilitating equalization, zero-setting, and diagnostics, and displaying the load distribution on each active channel.

- The perfect integration of the TLM8's CANopen protocol with the control unit allows real-time visualization of load cell diagnostics. The operator can immediately notice if a load cell has problems, while the service technician won't have to disassemble individual cells from the machine to find the faulty one.

- The combination of load cells and weight transmitter with the control unit allows monitoring the remaining product, ensuring uniform and precise distribution at any ground speed, reducing waste.

- The weighing system is so versatile that it is used not only on the fertilizer spreader, but on various models of agricultural machinery produced by SAM Machinery.

ПОХОЖИЕ ТОВАРЫ

FTP

Shear beam load cells

TLM8 CANOPEN

Weight transmitters